Inquire

cone crusher basics

Cone Crusher - an overview | ScienceDirect Topics

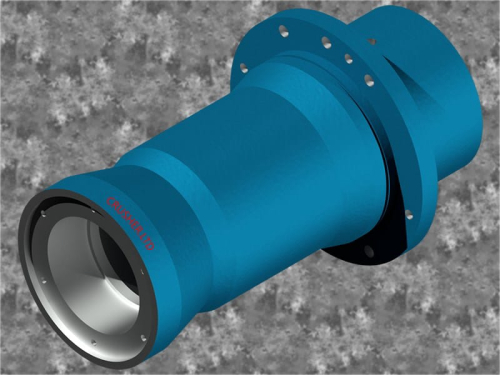

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are

Learn More

Cone crusher basics in 4 minutes - Mining and Rock Technology

Inside your cone crusher The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion.

Learn More

Cone Crusher Parts - 911 Metallurgist

Cone Crusher Components & Parts · SLEEVE TYPE SPIDER BEARING on larger size Hydrocone crushers is readily replaceable, greatly simplifies

Learn More

id/cone crusher crusher.md at main · /id - GitHub

Cone Crusher BOTTOM SHELL.The annealed cast steel bottom shell is of the three arm,open discharge type,bored to gauge for the top shell and eccentric bushing.It

Learn More

Application guide ® MP Series™ cone crusher wear parts

3 ® MP Series cone crusher MP Series cone crusher basic concepts 4 How to operate an MP Series cone crusher 5 4 The MP Series cone crusher is a compressive crusher that crushes feed material between a fixed bowl liner and a movable mantle.

Learn More

What affects cone crusher performance? — SRP

The primary contributor to poor crusher performance is crushing chamber selection. If the fit between the mantle and concave – in combination with the eccentric

Learn More

cone crusher model and its basic dimensions

Cone Crusher Manganese Wear Parts provide us with the model Previousknitting mills australia NextJaw Crusher basic Chat Now; cone crusher and mobile crusher for sale cone crusher model and its basic dimensions; crusher plant untuk batubara; deeper mill for foods; harga jual jaw crusher 600x900; sbm 11 11 4rhs crusher uk office; Chat Now

Learn More

Reliable Cone Crushers - CONETECH ENGINEERING

Each section of the CONETECH cone crushers has been designed and manufactured for durability. Frictionless labyrinth seal system offers great protection for the main bearing shell against dust. It allows the cone crusher to run cooler and requires less oil. Therefore, less motor power is wasted on friction and cooling. HYDRAULIC ANTI-SPIN SYSTEM

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement

Learn More

PDF) Cone Crusher Performance - ResearchGate

The basic operating principle of a cone crusher is shown in Figure 4. The properties, i.e. size. distribution and quality parameters, of the product leaving the crusher are a result of the.

Learn More

1 Minute to Cone Crusher Basics

This is the starting point for understanding how cone crushers work - and how they can improve the productivity of your mine or quarry. Inside your cone crusher The basic principle is simple: the material to be crushed (the feed material) falls into the crushing chamber. The mantle is a moving part that rotates in an eccentric motion.

Learn More